UK Concrete Roadmap to Beyond Net Zero

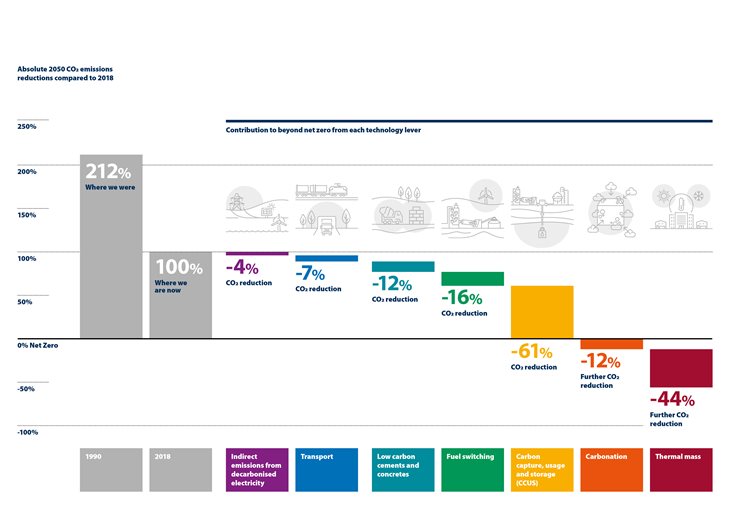

The UK concrete and cement industry Roadmap to Beyond Net Zero, published by UK Concrete part of the Mineral Products Association (MPA), has identified that net zero can be met through decarbonised electricity and transport networks, fuel switching, greater use of low-carbon cements and concretes as well as carbon capture technology for cement manufacture. Net negative can be achieved by 2050 when the in-use benefits of concrete structures are included.

The concrete and cement industry has already taken considerable early joint action and due to investment in fuel switching, changes in product formulation, and energy efficiency including plant rationalisation, its absolute direct and indirect emissions are 53% lower than 1990.

At a sector level, the MPA are working on a number of innovation projects that are milestones on the journey to decarbonise the manufacture of cement and concrete:

- Fuel switching

The cement industry already uses 14 alternative fuels to replace the use of fossil fuels, and 47% of the thermal energy used in the UK to manufacture cement is supplied from waste derived fuels. MPA Cement is building on this progress by undertaking ground-breaking demonstrations of hydrogen and plasma technology, which are being partly funded by the Department for Business, Energy and Industrial Strategy (BEIS) and will demonstrate the potential of these technologies to reduce carbon emissions through fuel switching from fossil fuels in cement and lime production.

Innovations in concrete and cement to use lower emission constituents are an important lever in the decarbonisation of the UK concrete and cement industry. In the UK there are many cements, with a range of embodied carbon, that can be specified in construction projects and concrete products. Ingredients such as clinker, alkali activators and supplementary cementitious materials (SCMs) are blended or inter-ground to form a fine powder called cement. Carbon emissions will be reduced by accelerating the use of the lower carbon concretes available now and the research and development into clinker content, alternative binders and cement formulations to increase the range of lower carbon concretes available.

- Low Carbon Cement and Concrete - Limestone

A Government-backed MPA research programme has successfully developed and trialled new low-carbon cements which have up to 60 per cent lower embodied CO2 emissions than CEM I.

During the two-year Carbon Trust-managed Industrial Energy Efficiency Accelerator programme, concretes containing 22 low-carbon multi-component cements were extensively tested for their durability and performance.

The research, supported by Hanson, the Building Research Establishment and Forterra Building Products, demonstrated that the new multi-component cements can lower carbon while meeting the performance requirements for general purpose cements in BS 8500.

When the update to BS 8500 is published it is expected that cement including limestone will become UK's standard cement (which is lower in carbon than the current market leader - CEM I). This limestone cement combination can then be blended with GGBS and fly ash to produce multi-component cements and lower carbon concrete.

- Low Carbon Cement and Concrete - Calcined Clay

MPA Cement are currently (as of 2022) in the first year of a two year project to trial the use of calcined clay in cement and concrete manufacture with the potential to reduce embodied carbon by 40 per cent. Funded by UK Research and Innovation (UKRI), the project will use calcined clay from brick manufacturing and reclaimed clay from other mineral extraction to assess the potential to reduce waste by 1.4 million tonnes. When the project is complete, the technical dossier will be available to provide confidence to designers to use calcined clays in general purpose concrete.

For more information visit www.thisisukconcrete.co.uk

UK Concrete and Cement Industry Roadmap to Beyond Net Zero

YouTube library

A world first technology demonstration project by the Mineral Products Association and Hanson UK has successfully seen a UK cement kiln operated using a net zero fuel mix including hydrogen for the very first time.