15 Oct 2020

We’re just about to start the third section of our virtual Sustainability Series, with this part looking in a more detail at the numbers and data that you can use for evaluating the sustainability of your project, either looking at the embodied carbon or at the whole lifecycle.

Much of the information is contained in our guidance document Specifying Sustainable Concrete and is downloadable for free. This version is dated February 2020 and contains the latest data from the Concrete Industry Sustainability Performance Report. It also contains the data from the latest version of MPA Cement’s Fact Sheet 18 and so is more up to date than the ICE Carbon Database.

In Specifying Sustainable Concrete, there are tables of embodied carbon for different aspects of reinforced concrete. One of the most useful is the table giving the embodied carbon for the main constituent parts:

One of the themes throughout Specifying Sustainable Concrete is that engineers and specifiers should use the right concrete for the location. The embodied carbon in concrete is very closely linked to cement content in the mix. It is therefore closely linked to the strength of the concrete as more cement in the mix will tend to give stronger concretes.

However, it is worth considering if a stronger concrete can be used to reduce the total volume of concrete. One of the comparisons in the book shows that using a C50/60 concrete for the columns in a building frame with C32/40 concrete for the slabs gave an overall saving in the embodied CO2 compared with using C32/40 concrete for both the slabs and the columns.

The other reason for using higher strength concretes is that they tend to be more durable than lower strength concretes, so should be used for more severe exposure classes. One point to note is that for internal concrete, exposure class XC1, the strength class could be as low as C20/25, for a 100 year intended working life, without having to use excessive cover.

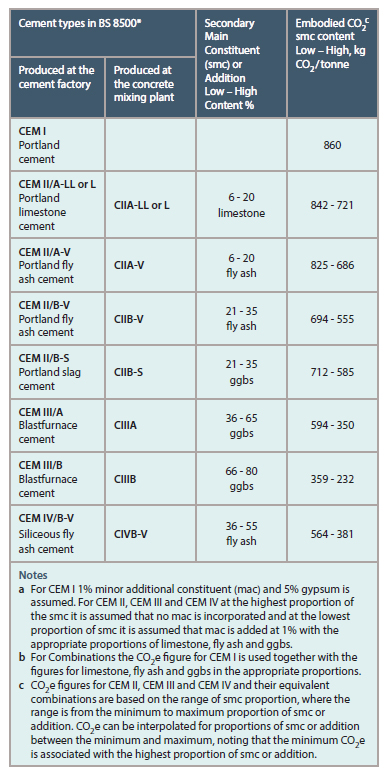

Another way of reducing the embodied carbon in concrete is to use cement replacements such as ground granulated blast-furnace slag (ggbs) or fly ash. The most recent version of the concrete specification code BS 8500 allows the use of ternary cements which are blends of CEM1 (Portland cement), ggbs or fly ash, and limestone fines.

Specifying Sustainable Concrete gives the embodied carbon in a range of different cements:

As you can see from the table, cements range in embodied carbon from 860kgCO2e/tonne at the maximum to 232kgCO2e/tonne for a CEMIIIB cement with 80% ggbs replacement. Such a high percentage of ggbs will influence the setting and strength gain of the concrete, and the book has some guidance on the strengths at seven days and 90 days for different concretes:

A standard way of specifying concrete is using designated concretes, where the concrete producer provides a concrete with a certain strength, consistency and maximum aggregate size. These are typical mixes that the concrete producer will have tested and used many times before. The book gives embodied carbon figures for some of these designated concretes with different levels of cement replacement.

This table shows how the embodied carbon changes with the use of the concrete and the cement type used.

Specifying Sustainable Concrete also has lots of information on the different types of aggregate and responsible sourcing of concrete. Since the concrete in the UK is a local product with most concrete made from cement and aggregates that come from within 50km, about 91% of precast and ready-mixed concrete is certified as responsibly sourced to BES6001 to ‘Very Good’ or ‘Excellent’ level.

It also means that, while recycled concrete aggregate can be used in concrete, the embodied carbon in the recycled aggregate will be higher than that for virgin aggregate if it is transported more than 15km. A final note on the embodied carbon of reinforcement. Currently the ICE Database has a figure of 1990kgCO2e/tonne for reinforcement. This is significantly higher than the 412kgCO2/tonne given in the first table.

The 412kgCO2e/tonne figure comes from the BAR eco-reinforcement scheme, all produced in the UK by the electric arc furnace (EAF) method from locally sourced scrap steel. The eco-reinforcement scheme can be specified, with an alternative of the CARES sustainability certification scheme, which has an average embodied carbon of 760kgCO2e/tonne, again significantly less than the ICE Database figure.

The events in the Navigating the Numbers theme are:

For more information visit the dedicated Sustainability Series page.

All of the events are free. Hope to see you there.

Written by: Jenny Burridge, Head of Structural Engineering, The Concrete Centre